Got Trees, Need Lumber?

Hiring a local sawmill operator to process your trees has many advantages. Saving money is always a consideration. If you have storm damaged or dying trees on your property, it could benefit you to have them milled into lumber rather than paying to have them disposed of. Milling custom sizes that are not available at the big box stores is one of the greatest advantages. Large table top material just cant be easily found and can be very pricey. Then there is the bragging rights that cant be found at the lumberyard. Your woodworking projects can be very gratifying and milling your own lumber can be a great way to save trees, time and money.

Before speaking to a Sawyer

Learn the lingo

Do you want flitch cut or quarter sawn? Maybe you need it all dimensional lumber or all cant’s. What is a board foot? See some of the common terms and definitions at the bottom of this page.

About Sawyers

As the saying goes; You can learn to operate a sawmill in one day, but it takes years to learn how to become a good Sawyer. As for myself, starting in 1995, it took me five years of working as a carpenter to pay off my mill, and during this time I butchered many nice logs learning how to be good at what I do. Recently on one of my jobs, I saw first hand how an inexperienced mill operator spent a full week milling what I was able mill in one day, and the waste pile he left amounted to a significant loss to the log owner. Reviews, testimonials, recommendations and years of experience are worth taking a good look at when choosing a competent Sawyer.

How do sawmills price their service?

Sawmill businesses typically charge by the board foot, or by the hour. What is a board foot? Rates vary from location to location and range from $65 to $125 per hour and can include extra charges for travel, damaged blades (nails), etc. Typically, higher prices reflect a more efficient, high production sawmills, where lower prices reflect smaller equipment being used and more time involved to produce the same amount lumber. Also, there is a difference between milling hardwood verses softwood. Daily volume is less when milling hardwoods such as Oak and Walnut. Log size and mill site conditions will all contribute to the end cost of lumber. It takes more time and handling to process small diameter and short logs, compared to large and long logs.

Is it cheaper to have my logs cut by a sawmill?

With the recent increase of lumber prices the short answer is yes. However, several factors must be considered to answer this question. First, cost of store bought lumber varies greatly depending on species of lumber and geographic location across the country. Another big factor is if you will incur a disposal fee from a tree service, as opposed to receiving lumber for a similar fee to have a sawmill cut your logs. A stationary sawmill needs to have logs and lumber transported back and forth. All these things must be factored in before knowing the final cost of your lumber.

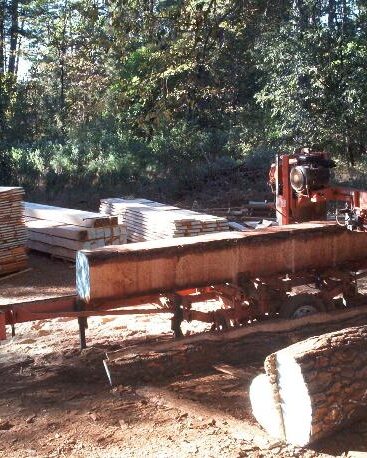

Logs and Mill Site

This is where your logs should be stacked and prepared, ready to begin milling. The better prepared you are the more cost effective your project will be. Portable sawmills will want to position right in front of your logs. They should have all branches cut close to the log, clean, and in an area with enough room to drive up to them with a pick-up towing a sawmill. The cost of your project will go up if logs are not assembled in one area and don’t have all the limbs removed. If your Sawyer has to stop milling and move logs or trim branches then production will go down and the price of your lumber goes up.

And finally, help.

If you are able to lend a hand this will keep the Sawyer making sawdust instead of offloading lumber, stacking, cleanup and moving logs. Many Sawyers will bring a helper for the times when log and land owners are not able to provide help. But beware! This is hard work. Everyone will be worn out at the end of the day.

Common Terms and Definitions

Cant

A portion of a log sawed on all four sides.

Cant Hook

This traditional logger’s tool is used to roll, lift, move, and pivot logs using the handle as a pivot lever. Two cant hooks are recommended for basic log handling capabilities. See Cant Hook

Dimensional Lumber

A term used for lumber that is cut to standardized width and thickness specified in inches. Examples of common lumber sizes are 2×4, 2×6, and 4×4.

Figure

Figure refers to grain pattern and can be a highly desired visual aspect. Types of figured wood may have names such as birds eye, cats paw burl, spalting, fiddle back, curly, vertical grain or cathedral grain.

Flitch

A portion of a sawn log which has bark on one or more sides. Also may be referred to as a “slab”.

Sawing to Grade

A sawing method where the log is sawn, turned to a new face, sawn and turned again up to five times to produce a higher grade of lumber. This may provide for a more stable type of lumber, a particular type of grain pattern or figure in the wood.

Grading

Evaluating and sorting trees, logs, or lumber according to quality, value and suitability for a specific purpose.

Hardwood

A term used to describe broadleaf (usually deciduous) trees. Oaks, Walnuts, Maples, Ashes, and Elms are hardwoods. .

Heartwood

The inner core of the tree. It is usually darker in color than the outer sapwood. Heartwood tends to be more resistant to rot and decay.

Kerf

The width of a cut made by a saw in a piece of wood. A smaller kerf means less sawdust and more lumber.

Log Scale

A table for calculating log volume in board feet based on log diameter and length. See Scribner, International, and Doyle log scales.

Moisture Content

The amount of water content in lumber or logs measured as a percentage of the lumber’s dry weight. In a living tree, wood has a moisture content of 75% or higher. For fine woodwork and cabinet making a moisture content should range from 7% to 14% depending on the average humidity in your geographic region. Overly dried lumber will swell up if transported to a location having a higher average humidity (doors will become tight and wont close). Conversely, wet wood may shrink in a dryer environment (fine joinery will crack, warp and gaps will open up). See Moisture Meter

Quarter Sawing

A sawing method generally defined as lumber sawn with growth rings at angles of 60 to 90 degrees to the widest face. Some quarter sawn lumber may be referred to as “Vertical Grain” or can produce a desirable “figure” in the lumber..

Sapwood

The outer part of a tree. Its main purpose is to carry water and store food. Sapwood tends to rot faster than the heartwood when exposed to the elements for prolonged periods of time.

Slash

What is left on the ground after logging, pruning, or other forest operations including tree tops, branches, and bark.

Stickers

Made of dry species of wood, stickers are wooden spacers placed between layers of lumber during drying. See Drying.

Stack

Several layers of stickered lumber. Also known as a pile. See Drying.

Tailings

The first cuts from a log that are considered waste, the bark sections or the drop off left over from the milling process.

Veneer

A thin sheet of wood. Veneer is often used for plywood facing, drawer and cabinet fronts and requires attachment to a stable sub straight (solid thicker material).